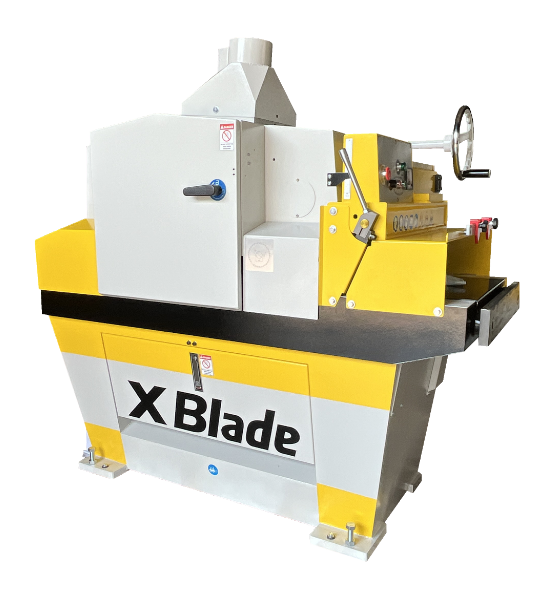

The robust and highly versatile X Blade Multirip saw provides powerful and high accuracy cutting for larger cross-section timber or where production output is critical. Its heavy-duty frame and feed track system ensures an exceptional quality of cut.