Quality Scanner for Longitudinal Transport with X-Ray

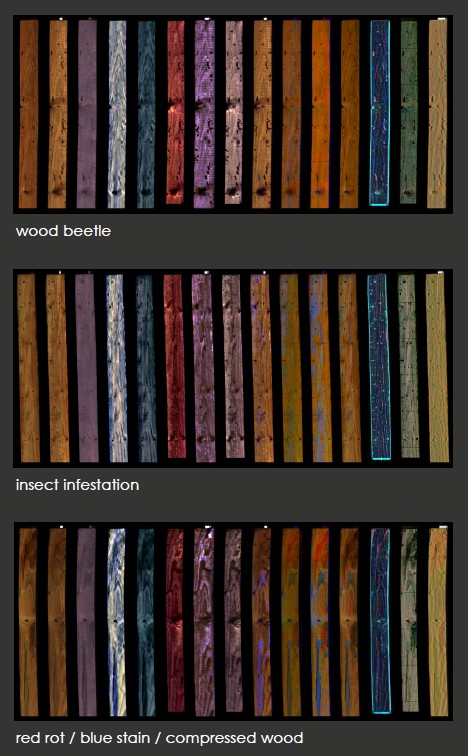

By using the Multisensor Quality Scanner Merlin QX, it is possible to reliably and accurately detect features and defects even inside the wood. This enables you to automate, streamline, and optimize your production. Through the combination of lasers, multispectral cameras, snapshot and X-ray technology, as well as artificial intelligence, the most precise scanning results are achieved, leading to a significant increase in added value.

Merlin QX is available in various customer-specific equipment variants.

Key Benefits

• Precise defect detection through the combination of multiple sensor technologies and artificial intelligence.

• Ideal for Industry 4.0 environments – full integration possible.

• Snapshot technology ensures consistent longitudinal resolution – independent of feed speed.

• Real-time classification using a single industrial PC.

• Flexible application for all wood types, formats, and quality grades.

• Intuitive user interface with real-time visual evaluation.