World-class machinery designed to drive efficiencies & transform the wood machining process.

Future-focused CNC tooling that delivers superior finishes and consistent performance.

A STIRLING GROUP COMPANY

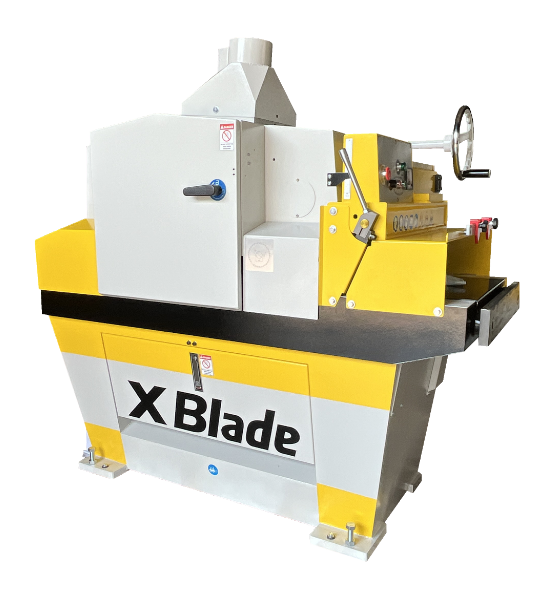

Stirling Machinery provides a range of CML machinery including multirips for all high volume hardwood timber workshops. Capable of making multiple high-tolerance rip cuts in a single pass, our multirips are versatile machines often employed for trimming, ripping and sizing large board and sheet stock into smaller components. Featuring a precision saw arbour, Stirling Machinery’s A Series and C Series multirips provide a powerful, high-accuracy machinery solution for most workshops. Offering unrivalled versatility, our multirip saws are perfect for use by sawmills, pallet makers, joiners, furniture makers and workshops producing engineered or moulded timber products.…

When production output is critical, our multrip saws deliver precision results and continuous, high-volume production. To protect staff and keep production moving, our multrips feature built-in safety systems and controls. The state-of-the-art safety technology on our multirips includes CE rated saw blade access locks, CE rated electrical cabinets, anti-kickback fingers and an instant braking system. Together with precision components, these safety features allow your workshop to achieve greater efficiency and reduce downtime.

…

To maximise your manufacturing capabilities, our multirips, like our finger joint machines, include robust construction and features that ensure they continue to perform time after time. Our A Series and C Series multirip saws include precision saw technology, durable chain conveyors and automatic lubrication systems to strike a balance between efficiency and accuracy. The chain drive through-feeds improve safety and reduce the need for operator input, making our multirips ideal for use in both manual and automated manufacturing workflows.

Stirling Machinery will work with you to design a multirip system that supports your manufacturing processes and delivers the performance you need. Whether you are trimming, sizing, dressing or simply ripping hardwood timber, we can design a multirip installation for your application. The feed track system on our multirips allows them to be paired with a variety of in and outfeed table configurations, including integration with automated feed systems.

Getting more from your machinery means providing your team with the training they need to work quickly, efficiently and safely. To ensure your new Stirling Machinery multirip performs as expected, our team can provide a customised training program to suit your operators. We always strive to match our customers with the perfect machine solution for their production needs, and our specially designed training methods deliver greater understanding to the operators who need it.

We also support clients with the ongoing maintenance required to keep their multirip saw or other machines like our tool cutter grinder in top condition. Our servicing, maintenance and repair programs look after your equipment, keeping it running smoothly and safely, even when the pressure is on. Our team provides tailored maintenance programs designed to keep up with your manufacturing requirements and ensure your equipment always performs at maximum capacity.

World-class machinery designed to drive efficiencies & transform the wood machining process.

Future-focused CNC tooling that delivers superior finishes and consistent performance.

Stirling Machinery © 2021 | All Rights Reserved