The A250/300 End Matcher is built to the latest design standards. Incorporating a number of time-saving and safety devices this machine has the ability to process material as short as 270mm and as wide as 300mm.

A STIRLING GROUP COMPANY

Home / Machines / End Matchers / A250/300 EM

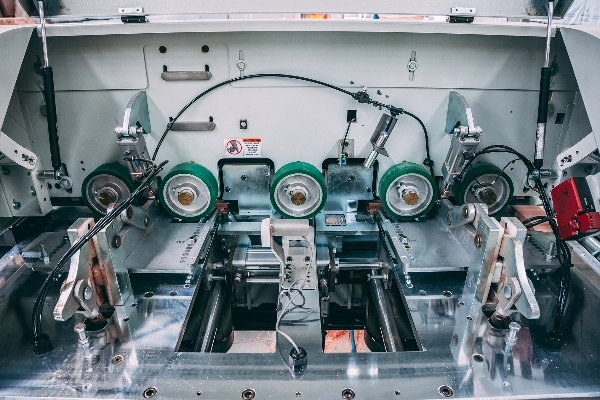

The A250/300 End Matcher is built to the latest design standards. Incorporating a number of time-saving and safety devices this machine has the ability to process material as short as 270mm and as wide as 300mm.

Comes with a touch screen to ensure maximum convenience of operation.

For maximum wear resistance.

Cutter speed is controlled by a frequency inverter that permits variable speed changes to suit a range of cutting conditions.

Each cutterhead is driven by independent, powerful motors.

Comes with a touch screen to ensure maximum convenience of operation.

For maximum wear resistance.

Cutter speed is controlled by a frequency inverter that permits variable speed changes to suit a range of cutting conditions.

Each cutterhead is driven by independent, powerful motors.

The A250/300 EM includes several key features to ensure the safe operation of the machine.

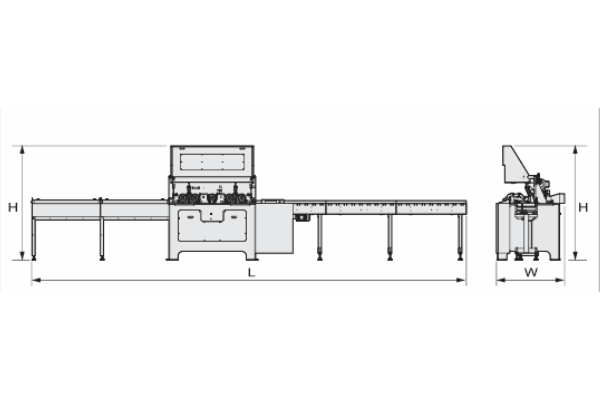

| Width (Min/Max) | 40 mm / 250 mm (300 mm Optional) |

| Thickness (Min/Max) | 10 mm / 35 mm |

| Timber Length (Min/Max) | 270 mm / Unlimited |

| Feed Speed | 90 m/min |

| End Trim & Profiling Speed (Based On 2 m Boards) | 24 m/min |

| Cut to End Trim, Profiling & Defect Cutting Speed (Based On 2 m Boards) | N/A |

If you’d like further information about the A250/300 EM, please call us on 1800 077 862, fill in the form below or email enquiries@stirlingmachinery.com.au.

World-class machinery designed to drive efficiencies & transform the wood machining process.

Future-focused CNC tooling that delivers superior finishes and consistent performance.

Stirling Machinery © 2021 | All Rights Reserved